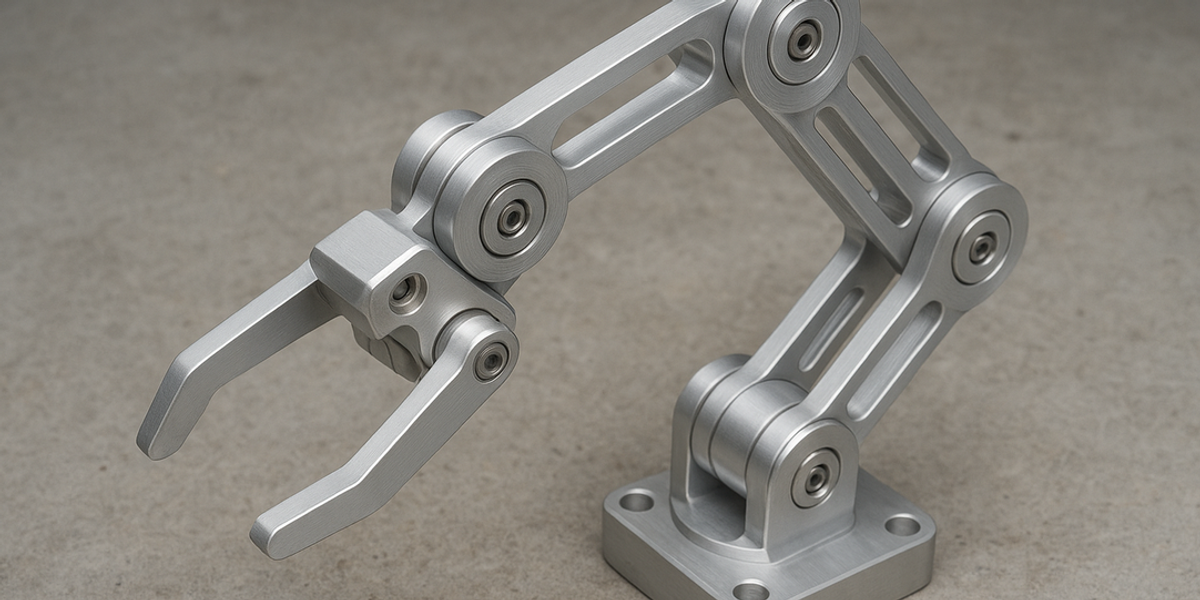

DFM Optimization Reduces Weight of Robotic Gripper Arm by 18%

Summary

The client required a lighter, more efficient gripper arm for their new line of assembly robots without compromising strength. Through strategic DFM analysis, we optimized the design for CNC milling, reducing part weight by 18% and decreasing cycle time, which directly improved the robot's operational speed and energy consumption.

The Challenge

Initial Need:

The client needed to produce a new robotic gripper arm from 6061-T6 aluminum that was both strong and lightweight to maximize the robot's payload capacity and movement speed.

Pain Points:

Their initial design, while functional, was over-engineered with thick walls and lacked features optimized for manufacturability. This resulted in excessive material usage and long machining times, driving up the projected unit cost.

Our Solution

Final Summary:

By implementing the DFM suggestions, we machined the gripper arms from solid 6061-T6 aluminum stock using 4-axis CNC milling. The optimized toolpaths and revised geometry cut the machining time by 22%. The final parts were deburred and finished with a Type II clear anodization for wear resistance.

Outcome

Value Comparison:

- Original Design: Unit Weight: 350g, Machining Time: 45 min, Relative Cost: 100%

- Optimized Design: Unit Weight: 287g (18% reduction), Machining Time: 35 min (22% reduction), Relative Cost: 82% (18% reduction)

Client Testimonial:

" "Their DFM feedback was invaluable. They didn't just make our part; they made it better, lighter, and more cost-effective. The 18% weight reduction directly translated to improved performance for our robots.""

- S. Jenkins, Lead Mechanical Engineer

Project Details

Processes:

- 4-Axis CNC Milling

- Tapping

- Deburring

Materials:

- Aluminum 6061-T6

Surface Finishes:

- Anodized Type II (Clear)

Industries:

- Robotics

- Automation

- Manufacturing