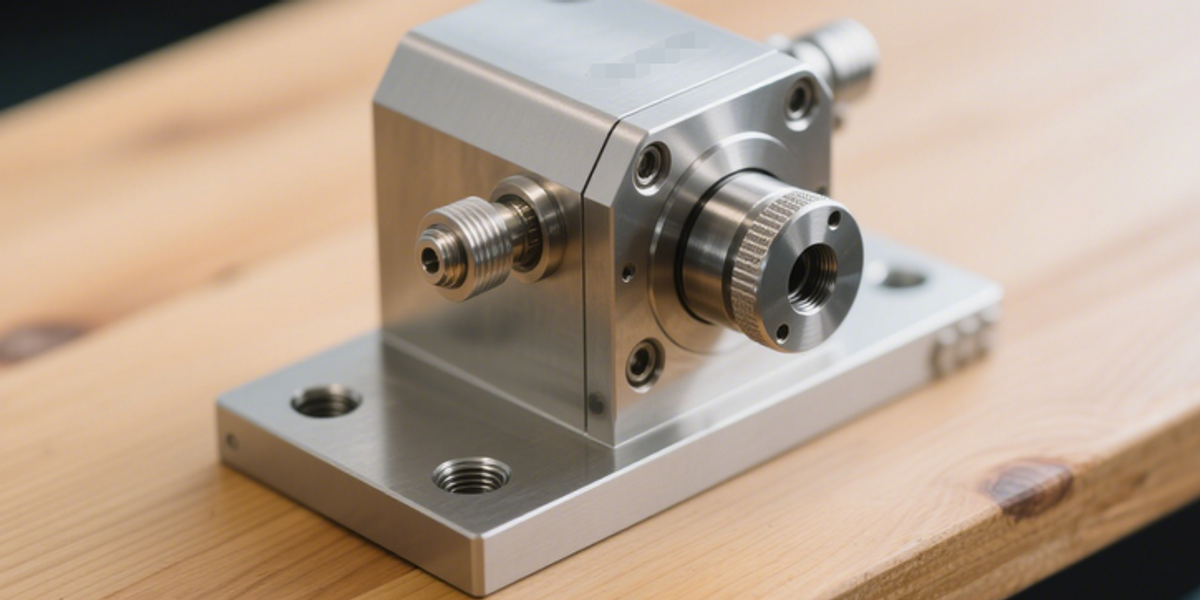

High-Precision Stainless Steel Mount for Optical Laboratory

Summary

The client required a mounting component for a new laser spectrometry device with extreme dimensional stability and tight tolerances to ensure precise optical alignment. We CNC machined the component from 316L stainless steel, holding a flatness tolerance of 0.005mm and positional tolerances of ±0.01mm, ensuring perfect, repeatable alignment of the sensitive optics.

The Challenge

Initial Need:

The component served as the foundation for a series of lenses and sensors. Any deviation in flatness or hole position would misalign the entire optical path, rendering the instrument useless. The material had to be 316L stainless steel for its low thermal expansion and corrosion resistance.

Pain Points:

The client's in-house machining capabilities could not consistently hold the required flatness over the part's 300mm length. They were experiencing warping and bowing after machining due to internal material stresses.

Our Solution

Final Summary:

The mount was machined on a high-precision vertical mill. The stress-relief cycle was critical. All critical features were inspected on our CMM (Coordinate Measuring Machine) to generate a full dimensional report, verifying that the flatness and positional tolerances were met. The final part had a fine, uniform machined finish.

Outcome

Value Comparison:

- Client's In-house Attempt: Flatness Achieved: ~0.05mm, Usability: Failed

- Our Process: Flatness Achieved: 0.004mm, Usability: Perfect alignment, 100% success rate

Client Testimonial:

""The precision is absolutely incredible. Their understanding of material science and their multi-stage machining process solved our warping problem completely. We now have perfectly stable and reliable optical mounts.""

- Dr. Reed, Chief Scientist

Project Details

Processes:

- Precision CNC Milling

- CMM Inspection

- Cryogenic Stress Relief

Materials:

- Stainless Steel 316L

Surface Finishes:

- As Machined (Ra 0.8 µm)

Industries:

- Scientific Instruments

- Optics

- Metrology

- Medical Devices